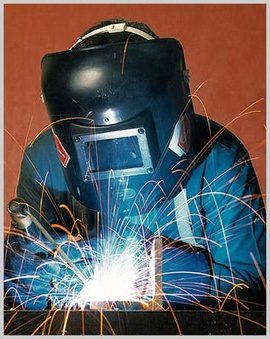

High-Quality Structural Welding Services

Structure Welders

Structural welders use aluminum, stainless steel and reinforced steel to erect structures that are often used in construction. Welding is done using a vareity of designs such as fillet weld, groove weld, weld length, partial joint penetration, lap joints, weld spacing, weld size, transitions and the static and cycling loading. Welders may work outside with very hot materials and sometimes at great heights.

Structure Fitters

Structural fitters will fit and join the often large pieces of metal used to complete the project and read and interpret building specs and blueprints to determine the size of the material and the optimum order to complete each step in the project. Fitters are required to operate a number of different types of equipment for hand tools, fabricating machines, welding torches, hoists or cranes while outdoors or in a noisy indoors environment, and often on scaffolds.

Pipe Fitters

Pipe fitters work on industrial piping systems, maintaining, installing, inspecting, and repairing the pipe systems and gauges and switches that operate the systems. Using tools such as electric scewdrivers, dies, levels, welding torches, and grinders. Pipe fitters have the ability to interpret technical drawings and plans.

Pipe Welders

Pipe welders are responsible for laying the metal pipes and using heat to melt and permanently join them. Horizontal rolled posisition (1G), horizontal fixed posistion (5G), pipe incline fixed (6G), and vertical position (2G), are some of the several different posistions used in welding. The ability to lift heavy objects, bend, stoop, and stand for long periods of time is part of the physical ability a pipe welder must have.

Training

All Structure Welders, Structure Fitters, Pipe Fitters and Pipe Welders for A. L. Loran International, LLC. go through a preliminary written exam, practical skill test, physical examination, and criminal background check.